Activities

The Micro Machining Group has been involved in the development and production of high-quality components for many years, thereby facilitating great achievements and breakthroughs.

The more specialised the requirement, the more the Micro Machining Group is in its element. The manufacture of such components is only possible when the most highly-skilled people are deployed in modern production facilities. At our production sites, we carry out all machining, mounting and assembly work, be it familiar or lesser known activities. Below you will find several examples of work on (assembled) products.

Product: Nozzle

- Market : Medical market

- Material: Austenitic steel

- Processes: Milling

- Heat treatment : none

- Surface treatment : none

- Size : 8 mm

Product: Housing

- Market: Oil and gas

- Material: Titanium

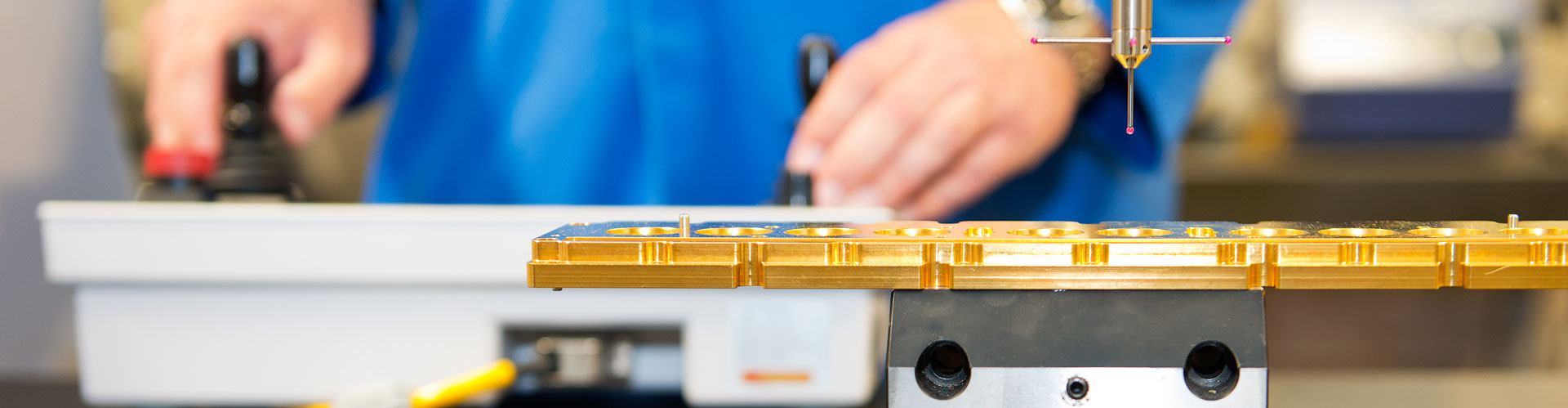

- Processes: CNC milling – 5-axis machining – deep hole drilling – 3D measuring

- Heat treatment: none

- Surface treatment: cleaning and clean packaging

- Size: 150mm x 80mm

Product: Measuring Instrument

- Market: Optical market

- Material : aluminium and stainless steel

- Processes: assembly, CNC machining, grinding and 3D testing

- Heat treatment: none

- Surface treatment: anodizing

- Size: 40mm x 50mm

Processes

The Micro Machining Group is able to carry out a wide variety of types of processing and activities ranging from the most sophisticated machining processes to special cleaning and packaging. Following you will find a selection of frequently occurring processes, but of course we would also like to give you more information about our full range of services and options.

CNC Machining

5-axis Machining

CNC Milling

Assembly

General machining

3D-measuring

Gluing

Conventional processes

Cleaning

Machining high-vacuum parts

Proto-parts

Micro-machining

Electrochemical Polishing

Orbital Welding

Assembly

CNC milling on staff

Grinding

Contact

We would like to get in touch with you about your specific challenges and questions. We would be pleased to give you a call but if you wish to contact us directly, please do so via the contact page. CONTACT PAGE